The energy of metal would make it just one of the most robust components recognised to humankind. When galvanized with zinc (Zn), it turns into far more resistant to corrosion. This helps make it an cost-effective option to use in development and infrastructure.

In the final ten years, Zn reserves have fallen appreciably, forcing us to switch to using Zn alloys. Magnesium (Mg) is the most usually used alloy mineral, and when utilized in small amounts it can enhance the corrosive resistance of Zn.

Now, Professor Myeong-Hoon Lee, Head of the Center of Floor Corrosion Command Engineering at Korea Maritime and Ocean University, and his colleagues have proposed a novel coating for steel that claims to improve its longevity. “During my time in the navy, I recognized a good deal of devices that have been rusting. So, I engaged in this analysis, hoping to create better anti-corrosive steel,” says Prof. Lee, outlining his commitment driving the review.

“To survive in severe environments, substantial anti-corrosive materials have to have to be formulated. Steel is one these kinds of materials and rising its everyday living span would make the steel a lot more sustainable,” Prof. Lee explains. Their research was released in Corrosion Science.

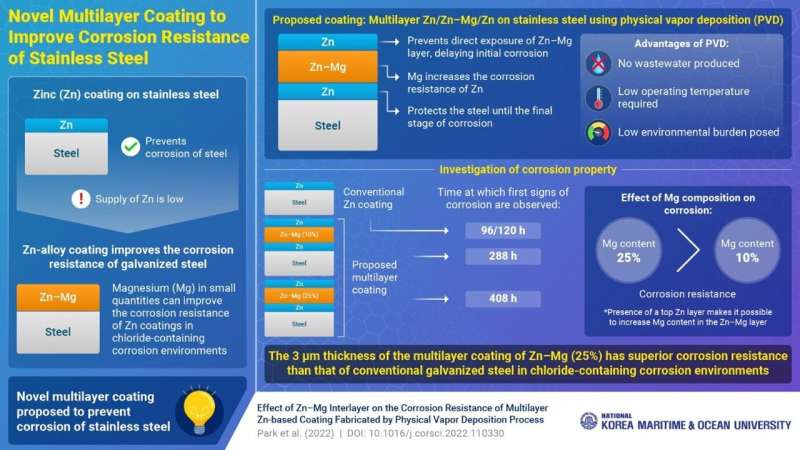

The proposed multilayer coating includes a few levels fabricated utilizing actual physical vapor deposition (PVD). A Zn–Mg layer is sandwiched concerning two Zn layers. The prime Zn layer protects the Zn–Mg layer from staying in get in touch with with the corrosive setting. The previous line of defense for the metal is the bottom Zn layer.

Two samples had been prepared to take a look at the corrosion resistance of this modified steel—one that contains 10% Mg and the other 25% Mg. The staff found that the symptoms of rust appeared at 208 hrs and 408 several hours for the 10% and 25% compositions, respectively, when in contrast with 96/120 hrs for typical Zn coatings.

Up coming, they as opposed the corrosion resistance of the two compositions. They discovered that the 25% composition has a higher resistance to rust than the 10% a person. This was contrary to past experiences suggesting Mg information higher than 8% lowers the corrosion resistance of steel. The experts attributed this contradictory locating to the presence of the top rated Zn layer, which manufactured it attainable to maximize the Mg written content in the Zn–Mg layer.

“The multilayer coating on steel helps make it hugely stable, inexpensive, and durable, creating it an excellent alternative for use in harsh environments,” concludes Prof. Lee.

Suiting up with Al-Mg-Si: New protective coating for steel in ships and maritime and coastal facilities

Jae-Hyeok Park et al, Influence of Zn-Mg interlayer on the corrosion resistance of multilayer Zn-based coating fabricated by actual physical vapor deposition approach, Corrosion Science (2022). DOI: 10.1016/j.corsci.2022.110330

Presented by

Countrywide Korea Maritime and Ocean University

Quotation:

The important is in the coating: Multilayered coating to make improvements to the corrosion resistance of steel (2022, July 7)

retrieved 7 July 2022

from https://phys.org/news/2022-07-critical-coating-multilayered-corrosion-resistance.html

This document is matter to copyright. Aside from any truthful working for the purpose of non-public examine or study, no

portion may perhaps be reproduced with no the prepared authorization. The content is furnished for information and facts applications only.