Contents

Setting your foot in the manufacturing industry? There are many things to learn about – especially with all the manufacturing devices you can not miss at any cost.

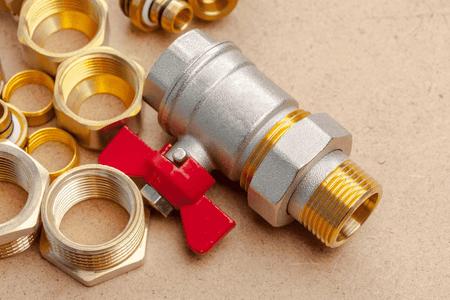

Among so many devices, one of the most essential devices is a ball valve. The ball valves come in different varieties – including 1-piece, 2-piece, or 3-piece ball valves.

Among these options, a 1-piece ball valve (usually available as a reduced port ball valve) is a widely used variety.

With its single-piece cast body, the chances of leakage are reduced to a greater extent. In addition, the costs are significantly reduced if you opt for this variation.

Want to learn more about the importance of this critical control device? You have reached the right place!

With no further delay, let us learn more about one-port ball valves in this blog:

One-Piece Ball Valve: What Is It?

A one-piece ball valve is a type of valve used to control the flow of fluids in a piping system. It comprises a single-piece body with a hollow, perforated, and pivoting ball inside.

The ball has a hole or port through the center, which, when aligned with the valve ends, allows fluid to flow through and, when turned perpendicular, blocks the flow.

Reduced port ball valves are typically used in applications where a simple on/off control of the fluid flow is needed. They are known for their reliability, ease of operation, and minimal maintenance requirements.

How Does It Work?

The operation of valves with single-piece cast body is relatively straightforward:

Open Position: When the valve handle is turned so that the bore of the ball is in line with the pipeline, the valve is in the open position. This allows fluid to flow through the valve unimpeded.

Closed Position: When the handle is turned perpendicular to the pipeline, the bore of the ball becomes perpendicular to the flow, effectively blocking the fluid passage. This is the closed position of the valve.

Flow Control: The handle’s position determines the flow control degree. By partially turning the handle, the operator can adjust the flow rate by partially obstructing the passage with the ball.

The mechanism inside the valve is the spherical ball with a hole bored through its center. When the valve is in the open position, the hole in the ball is aligned with the flow direction, allowing fluid to pass through.

When the valve is closed, the ball is rotated so the hole is perpendicular to the flow, blocking the passage entirely.

Advantages of Using Reduced Port Ball Valve

One-piece ball valves offer several advantages over other types of valves, including:

Simplicity and Reliability: A simple design with fewer components makes it easier to manufacture, assemble, and maintain. This simplicity also enhances their reliability, as there are fewer potential points of failure.

Tight Shut-off: These valves provide excellent sealing properties when closed, ensuring a tight shut-off and preventing leakage of fluids through the valve.

Smooth Flow Control: The spherical design of the ball allows for smooth and precise flow control. By simply turning the handle or actuator, the operator can adjust the flow rate quickly and accurately.

Versatility: Reduced port ball valves can be used in various applications and industries, including industrial, commercial, and residential plumbing systems, as well as in various process industries such as oil and gas, chemical, and pharmaceuticals.

Durability: These valves are typically made from durable materials such as stainless steel, brass, or PVC, which ensures their longevity and resistance to corrosion and wear.

Low Maintenance: Due to their simple design and robust construction, these simpler valves require minimal maintenance over their operational lifetime, resulting in cost savings for the user.

Cost-effectiveness: The most significant benefit offered by the valves is often more cost-effective than other valves, making them a preferred choice for many applications where budget constraints are a concern.

Disadvantages of Using Reduced Port Ball Valve

While one-piece ball valves offer several advantages, they also have some limitations and potential disadvantages, including:

Limited Sizes and Pressure Ratings: Valves with one body piece are typically available in smaller sizes and have lower pressure ratings than other types of valves, such as two-piece or three-piece ball valves. This can restrict their use in applications requiring higher pressures or larger pipe sizes.

Limited Seat Material Options: One-piece ball valves often have integrated seats made from the same material as the valve body. This limits the choice of seat materials available, which may not be suitable for certain applications where specific seat materials are required for compatibility with the fluid being handled.

Less Flexibility in Installation: Reduced port ball valves have a fixed body configuration, which may limit their flexibility during installation, especially in tight spaces or complex piping arrangements. In contrast, multi-piece ball valves offer more flexibility as they can be disassembled and reassembled if needed.

Conclusion

The one-piece ball valve, especially in its reduced port configuration, is critical in fluid control systems across various industries.

Its simple yet reliable design offers numerous advantages, including tight shut-off capabilities, smooth flow control, and versatility.

As industries continue to evolve and innovate, the role of one-piece ball valves in fluid control systems is expected to remain significant.

With this, keep exploring and keep learning!