[ad_1]

So how substantially of the material that goes into the usual bin avoids a trip to landfill? For nations around the world that do curbside recycling, the number—called the restoration rate—appears to average all around 70 to 90 p.c, while common facts is not available. That doesn’t look undesirable. But in some municipalities, it can go as lower as 40 %.

What is even worse, only a small amount of all recyclables will make it into the bins—just 32 percent in the United States and 10 to 15 percent globally. That is a lot of material produced from finite methods that needlessly goes to squander.

We have to do greater than that. Correct now, the recycling field is facing a economical disaster, many thanks to falling prices for sorted recyclables as perfectly as coverage, enacted by China in 2018, which restricts the import of a lot of resources destined for recycling and shuts out most recyclables originating in the United States.

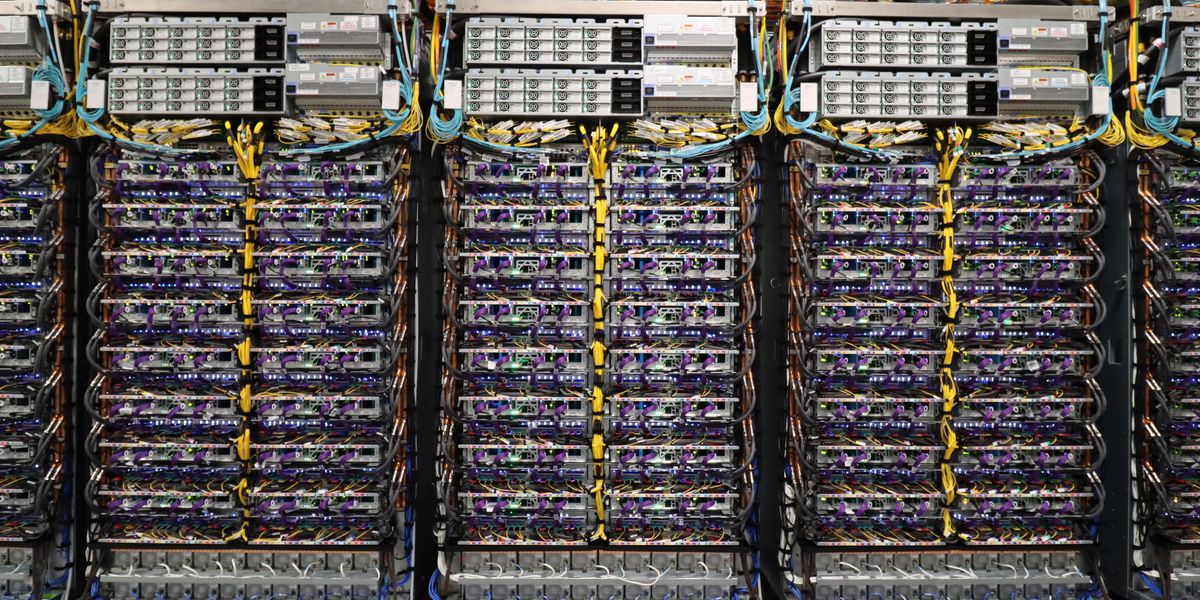

There is a way to do superior. Applying computer vision, machine learning, and robots to determine and form recycled materials, we can increase the accuracy of automatic sorting machines, cut down the want for human intervention, and raise overall recovery rates.

My organization,

Amp Robotics, primarily based in Louisville, Colo., is creating hardware and software that relies on impression examination to type recyclables with considerably larger precision and restoration costs than are usual for regular techniques. Other companies are in the same way functioning to implement AI and robotics to recycling, which include Bulk Managing Devices, Machinex, and Tomra. To day, the technological know-how has been mounted in hundreds of sorting facilities all-around the environment. Expanding its use will reduce waste and assistance the natural environment by holding recyclables out of landfills and creating them less difficult to reprocess and reuse.

Ahead of I demonstrate how AI will strengthen recycling, let’s search at how recycled resources were sorted in the past and how they’re remaining sorted in most sections of the environment today.

When recycling began in the 1960s, the job of sorting fell to the consumer—newspapers in a person bundle, cardboard in an additional, and glass and cans in their very own separate bins. That turned out to be way too significantly of a headache for quite a few individuals and confined the total of recyclable products gathered.

In the 1970s, many cities took absent the numerous bins and replaced them with a single container, with sorting going on downstream. This “single stream” recycling boosted participation, and it is now the dominant variety of recycling in developed nations.

Going the job of sorting more downstream led to the building of sorting facilities. To do the precise sorting, recycling entrepreneurs adapted machines from the mining and agriculture industries, filling in with human labor as necessary. These sorting units had no personal computer intelligence, relying as a substitute on the physical qualities of supplies to different them. Glass, for case in point, can be damaged into small pieces and then sifted and gathered. Cardboard is rigid and light—it can glide more than a sequence of mechanical camlike disks, when other, denser materials drop in between the disks. Ferrous metals can be magnetically separated from other elements magnetism can also be induced in nonferrous items, like aluminum, using a massive eddy recent.

By the 1990s, hyperspectral imaging, created by NASA and very first released in a satellite in 1972, was turning into commercially practical and commenced to display up in the recycling world. In contrast to human eyes, which mainly see in combos of red, environmentally friendly, and blue, hyperspectral sensors divide photographs into a lot of far more spectral bands. The technology’s skill to distinguish amongst unique kinds of plastics improved the sport for recyclers, bringing not only optical sensing but computer system intelligence into the method. Programmable optical sorters were also formulated to separate paper goods, distinguishing, say, newspaper from junk mail.

So nowadays, much of the sorting is automatic. These systems normally kind to 80 to 95 per cent purity—that is, 5 to 20 per cent of the output shouldn’t be there. For the output to be financially rewarding, nevertheless, the purity must be bigger than 95 p.c under this threshold, the worth drops, and normally it is truly worth absolutely nothing. So people manually clean up each of the streams, picking out stray objects right before the material is compressed and baled for shipping and delivery.

Despite all the automated and handbook sorting, about 10 to 30 percent of the product that enters the facility ultimately ends up in a landfill. In most circumstances, much more than 50 % of that material is recyclable and value funds but was simply skipped.

We’ve pushed the current systems as far as they can go. Only AI can do far better.

Receiving AI into the recycling small business means combining select-and-place robots with accurate serious-time item detection. Pick-and-place robots combined with computer system vision devices are utilised in manufacturing to seize unique objects, but they frequently are just looking repeatedly for a one item, or for a several things of recognized styles and beneath controlled lights situations.Recycling, even though, includes infinite variability in the kinds, designs, and orientations of the objects touring down the conveyor belt, necessitating almost instantaneous identification together with the swift dispatch of a new trajectory to the robotic arm.

My business 1st began working with AI in 2016 to extract vacant cartons from other recyclables

at a facility in Colorado nowadays, we have units put in in far more than 25 U.S. states and six nations around the world. We weren’t the to start with business to test AI sorting, but it hadn’t earlier been used commercially. And we have steadily expanded the forms of recyclables our devices can identify and form.

AI helps make it theoretically doable to recover all of the recyclables from a mixed-product stream at precision approaching 100 percent, completely primarily based on impression assessment. If an AI-centered sorting technique can see an item, it can accurately type it.

Consider a notably tough substance for today’s recycling sorters: superior-density polyethylene (HDPE), a plastic normally employed for detergent bottles and milk jugs. (In the United States, Europe, and China, HDPE products and solutions are labeled as No. 2 recyclables.) In a method that depends on hyperspectral imaging, batches of HDPE are likely to be combined with other plastics and may have paper or plastic labels, building it difficult for the hyperspectral imagers to detect the underlying object’s chemical composition.

An AI-driven pc-eyesight process, by distinction, can identify that a bottle is HDPE and not anything else by recognizing its packaging. Such a method can also use characteristics like coloration, opacity, and sort factor to enhance detection accuracy, and even kind by coloration or distinct product, cutting down the quantity of reprocessing essential. Nevertheless the program doesn’t attempt to fully grasp the indicating of terms on labels, the terms are element of an item’s visible attributes.

We at AMP Robotics have built devices that can do this sort of sorting. In the foreseeable future, AI devices could also type by combinations of product and by initial use, enabling foodstuff-grade products to be separated from containers that held family cleaners, and paper contaminated with foods squander to be divided from cleanse paper.

Education a neural community to detect objects in the recycling stream is not simple. It is at the very least various orders of magnitude much more demanding than recognizing faces in a photograph, since there can be a nearly infinite range of approaches that recyclable elements can be deformed, and the method has to figure out the permutations.

It’s tricky plenty of to educate a neural community to establish all the distinctive forms of bottles of laundry detergent on the market right now, but it is an completely distinctive challenge when you contemplate the physical deformations that these objects can endure by the time they arrive at a recycling facility. They can be folded, torn, or smashed. Blended into a stream of other objects, a bottle could have only a corner obvious. Fluids or food squander may obscure the product.

We prepare our systems by offering them visuals of components belonging to every class, sourced from recycling services all around the world. My corporation now has the world’s biggest data established of recyclable materials pictures for use in equipment studying.

Utilizing this knowledge, our versions understand to recognize recyclables in the very same way their human counterparts do, by spotting patterns and functions that distinguish distinctive resources. We continuously collect random samples from all the facilities that use our methods, and then annotate them, insert them to our databases, and retrain our neural networks. We also examination our networks to obtain styles that complete finest on concentrate on materials and do qualified extra schooling on supplies that our techniques have difficulty identifying the right way.

In typical, neural networks are inclined to studying the improper detail. Images of cows are related with milk packaging, which is typically made as a fiber carton or HDPE container. But milk products can also be packaged in other plastics for example, single-serving milk bottles may well look like the HDPE of gallon jugs but are ordinarily built from an opaque sort of the PET (polyethylene terephthalate) applied for water bottles. Cows really do not often mean fiber or HDPE, in other text.

There is also the obstacle of being up to date with the continual alterations in client packaging. Any mechanism that depends on visual observation to master associations concerning packaging and content varieties will require to eat a steady stream of knowledge to ensure that objects are categorised accurately.

But we can get these units to work. Ideal now, our techniques do definitely nicely on particular categories—more than 98 per cent precision on aluminum cans—and are getting greater at distinguishing nuances like color, opacity, and preliminary use (recognizing those people meals-grade plastics).

Now thatAI-dependenttechniques are completely ready to take on your recyclables, how might things transform? Unquestionably, they will boost the use of robotics, which is only minimally utilized in the recycling sector nowadays. Specified the perpetual employee shortage in this dull and dirty enterprise, automation is a path worth getting.

AI can also assistance us recognize how well today’s existing sorting processes are accomplishing and how we can strengthen them. Now, we have a quite crude being familiar with of the operational performance of sorting facilities—we weigh vans on the way in and weigh the output on the way out. No facility can tell you the purity of the products with any certainty they only audit top quality periodically by breaking open random bales. But if you positioned an AI-run vision method over the inputs and outputs of appropriate pieces of the sorting method, you’d attain a holistic view of what materials is flowing exactly where. This degree of scrutiny is just commencing in hundreds of facilities close to the planet, and it must guide to larger effectiveness in recycling functions. Being able to digitize the real-time move of recyclables with precision and regularity also offers options to improved comprehend which recyclable resources are and are not currently becoming recycled and then to identify gaps that will make it possible for services to boost their recycling devices total.

Sorting Robot Finding Combined PlasticsAMP Robotics

But to actually unleash the ability of AI on the recycling approach, we want to rethink the overall sorting course of action. These days, recycling operations ordinarily whittle down the mixed stream of materials to the focus on material by getting rid of nontarget material—they do a “negative kind,” in other terms. Instead, making use of AI vision devices with robotic pickers, we can carry out a “positive sort.” In its place of removing nontarget material, we establish each individual item in a stream and find the goal content.

To be guaranteed, our restoration charge and purity are only as fantastic as our algorithms. All those figures proceed to increase as our units achieve far more expertise in the world and our training data established carries on to develop. We expect to at some point strike purity and restoration premiums of 100 per cent.

The implications of moving from far more mechanical methods to AI are profound. Alternatively than coarsely sorting to 80 % purity and then manually cleaning up the stream to 95 % purity, a facility can arrive at the target purity on the 1st pass. And as an alternative of acquiring a special sorting system dealing with each and every type of product, a sorting machine can adjust targets just by a switch in algorithm.

The use of AI also suggests that we can recover products very long disregarded for economic good reasons. Right up until now, it was only economically feasible for facilities to go after the most ample, large-worth goods in the waste stream. But with machine-understanding techniques that do beneficial sorting on a wider wide variety of components, we can get started to capture a higher diversity of content at tiny or no overhead to the business enterprise. Which is very good for the planet.

We are starting to see a number of AI-centered secondary recycling amenities go into procedure, with Amp’s engineering very first coming online in Denver in late 2020. These techniques are currently made use of where product has now handed by a standard type, looking for significant-price resources skipped or lower-worth resources that can be sorted in novel strategies and as a result uncover new markets.

Thanks to AI, the field is starting to chip absent at the mountain of recyclables that conclusion up in landfills just about every year—a mountain made up of billions of tons of recyclables representing billions of bucks lost and nonrenewable sources wasted.

This write-up seems in the July 2022 print concern as “AI Will take a Dumpster Dive .”